Aug. 21, 2023

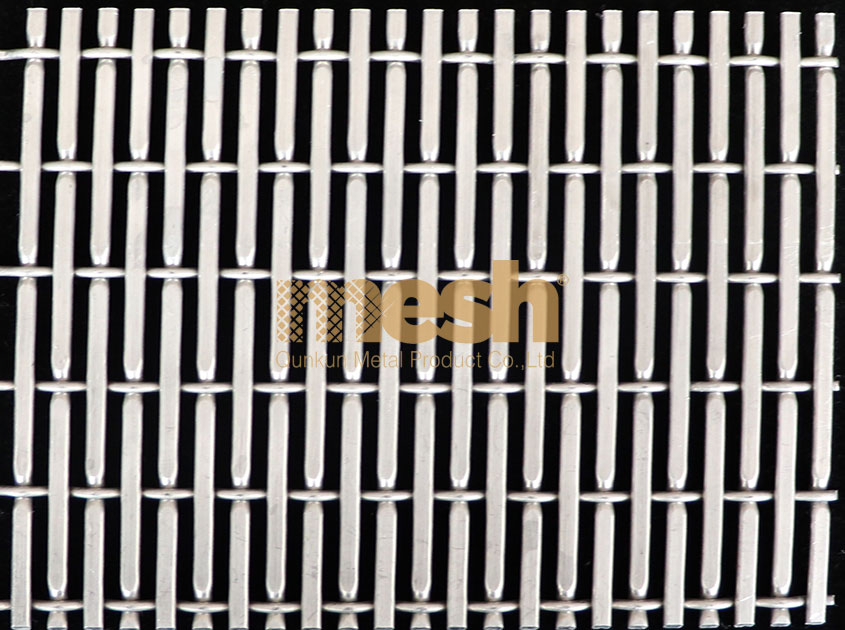

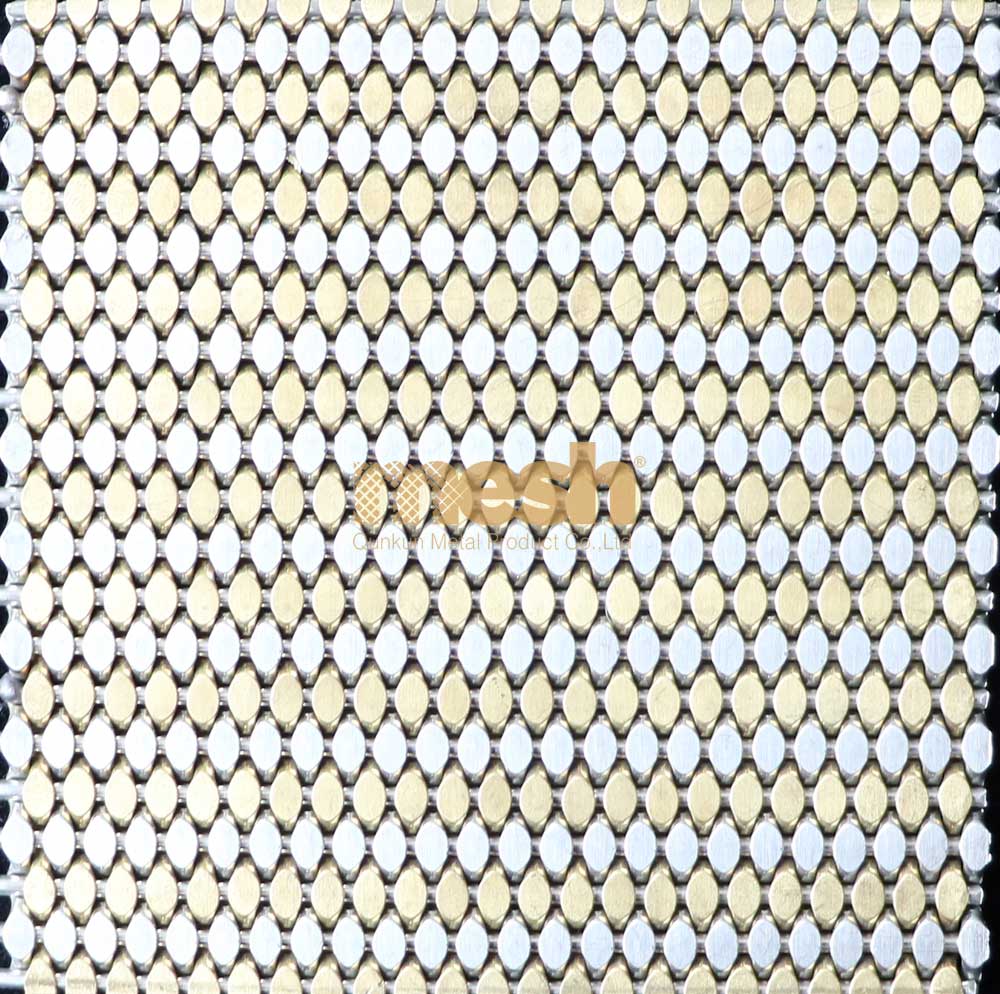

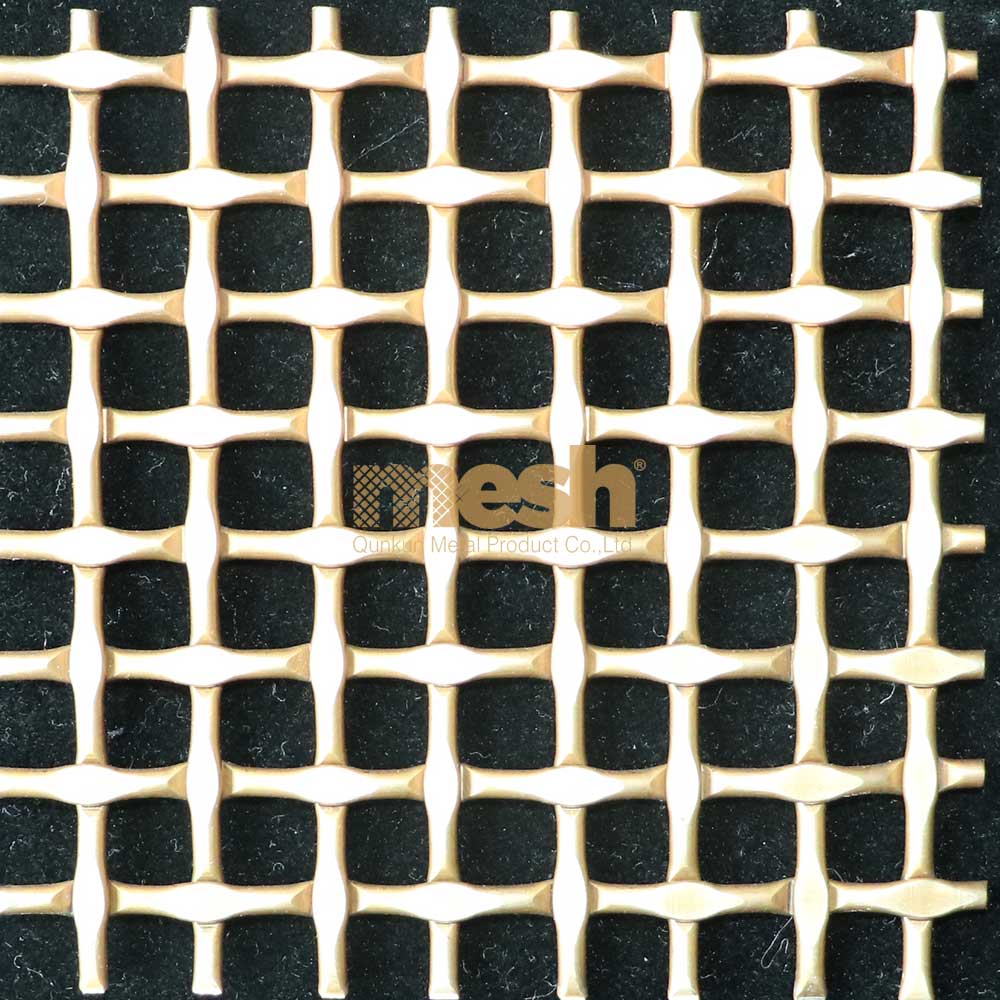

As a multi-purpose screening material, Crimped Woven Mesh plays an important role in various fields. In order to enhance its durability and functionality, surface treatment has become a link that cannot be ignored.

Galvanized treatment: a barrier against corrosion

Galvanizing is a common surface treatment that resists corrosion by forming a protective layer of zinc on the surface of the Crimped Woven Mesh. The advantage of galvanizing is its ability to resist corrosion, making the Crimped Woven Mesh more durable in harsh environments. This treatment extends the life of the woven screen, ensuring long-lasting reliability in a variety of applications.

Coating Technology: Functional Enhancement and Decorative Effects

In addition to galvanizing, coating techniques are also an option for the surface treatment of Crimped Woven Mesh. By applying coatings on the surface of the screen, different functions can be achieved, such as anti-corrosion, anti-scratch, etc. At the same time, the coating can also increase the decorativeness of the woven screen, making it better integrated into various environments.

Regardless of the finishing method used, regular maintenance is key to maintaining the long-lasting results of your Crimped Woven Mesh. Regular cleaning and inspection, and timely repair of damaged parts can ensure that the effect of surface treatment can be maintained for a long time, so that the woven mesh can always maintain its function and beauty. By deeply understanding the surface treatment method of Crimped Woven Mesh, you can better choose suitable The treatment method improves the performance and durability of the woven screen.

Decorative wire mesh: the perfect blend of art and life

Metal Decor Website, Customized Metal Decor Products Professionally

Hot Products

NAVIGATION

Contact Us

Phone:

+86 151 2815 1778

FAX:

+86 311 8961 3055

Address:

No.77, The Wire Mesh Filter Industrial Zone of Anping, Hebei, China